CHALLENGES

Testimonials and Success Stories

Plastics for Zero Emissions – Turning Waste into Value with Photolysis

Our Vision

At Grensol, we believe that one of the greatest challenges of our time is to transform waste into resources. Automotive Shredder Residue (ASR), the complex plastic fraction left after vehicle recycling, has long been a problem. In Switzerland, this material is still incinerated, which destroys valuable raw materials and creates additional emissions. Our vision was clear: if we could find a way to unlock the value of this waste, we could make a meaningful contribution to a low-emission, circular economy.

Our Approach

With the support of the Plastics for Zero Emissions Innobooster program, we set out to test a new solution: Photolysis, a process that uses high-energy light flashes to break down polymers within milliseconds. Together with our scientific partner, HEIG-VD, we developed a dedicated reactor and carried out experiments both on pure plastics – polyurethane, polyethylene, polypropylene, and more – and on ASR samples provided by Swiss car recyclers.

The results were exciting. The process converted the material into syngas (mainly methane, hydrogen, carbon monoxide) and carbon black – two valuable resources with industrial potential. Detailed analyses confirmed the composition of these products and showed clear pathways for improving their quality through post-treatment.

Our Results

For me as CEO, what matters most is proof of concept and future scalability. And this project delivered exactly that, which has encouraged us to take the long journey towards industrialising this solution:

- We demonstrated that all tested plastics and ASR can be transformed into useful products.

- The recovered carbon black already contained up to 35% carbon and can be refined to reach industrial grade (>85%).

- The syngas fraction holds promise for energy applications, particularly due to its hydrogen content.

- Some metals and minerals remained in the solid fraction, offering further material recovery opportunities.

In short: we proved that ASR does not have to be burned – it can be turned into value.

Our Partners

This project would not have been possible without a strong network. At HEIG-VD, Dr. Xenia Christodoulou and Julien Ropp brought their deep experience in waste valorisation and reactor design. And of course, Swiss car recyclers played a crucial role by providing real-world ASR samples from their recycling operations.

Looking Ahead

This project confirmed what I have always believed: innovation can turn today’s waste into tomorrow’s resources. With further optimisation, Photolysis can become a key technology for sustainable plastics management – enabling cleaner energy, circular materials, and a reduction in emissions. At Grensol, we are committed to driving this vision forward and overcoming the numerous challenges we will face in this journey.

By Rajiv Singhal, CEO Grensol

Feasibility Study – Recycling Landfill Plastics in Tännlimoos

My Motivation

As a Team leader of Recycling and Disposal at JURA Materials, I often deal with plastics recovered from landfill remediation. These materials lose their quality over time and are usually incinerated in the end. For me, the goal was clear: if we could find a way to recycle these materials, we could create real value for the environment and society while making landfill remediation more economically attractive.

Our Approach

Together with the Lucerne University of Applied Sciences and Arts (HSLU) and the Fraunhofer Institute for Chemical Technology (ICT), we launched a feasibility study to test whether old landfill plastics can be turned into high-quality recycled materials. Our starting point was PE sealing sheets from the Tännlimoos landfill site in Zug, Switzerland.

The HSLU team was responsible for cleaning, sorting, and chemically analyzing the samples, while Fraunhofer ICT tested both mechanical and solvent-based recycling processes. My role was to coordinate the work on the landfill site and ensure a smooth connection between practice and research.

First Results

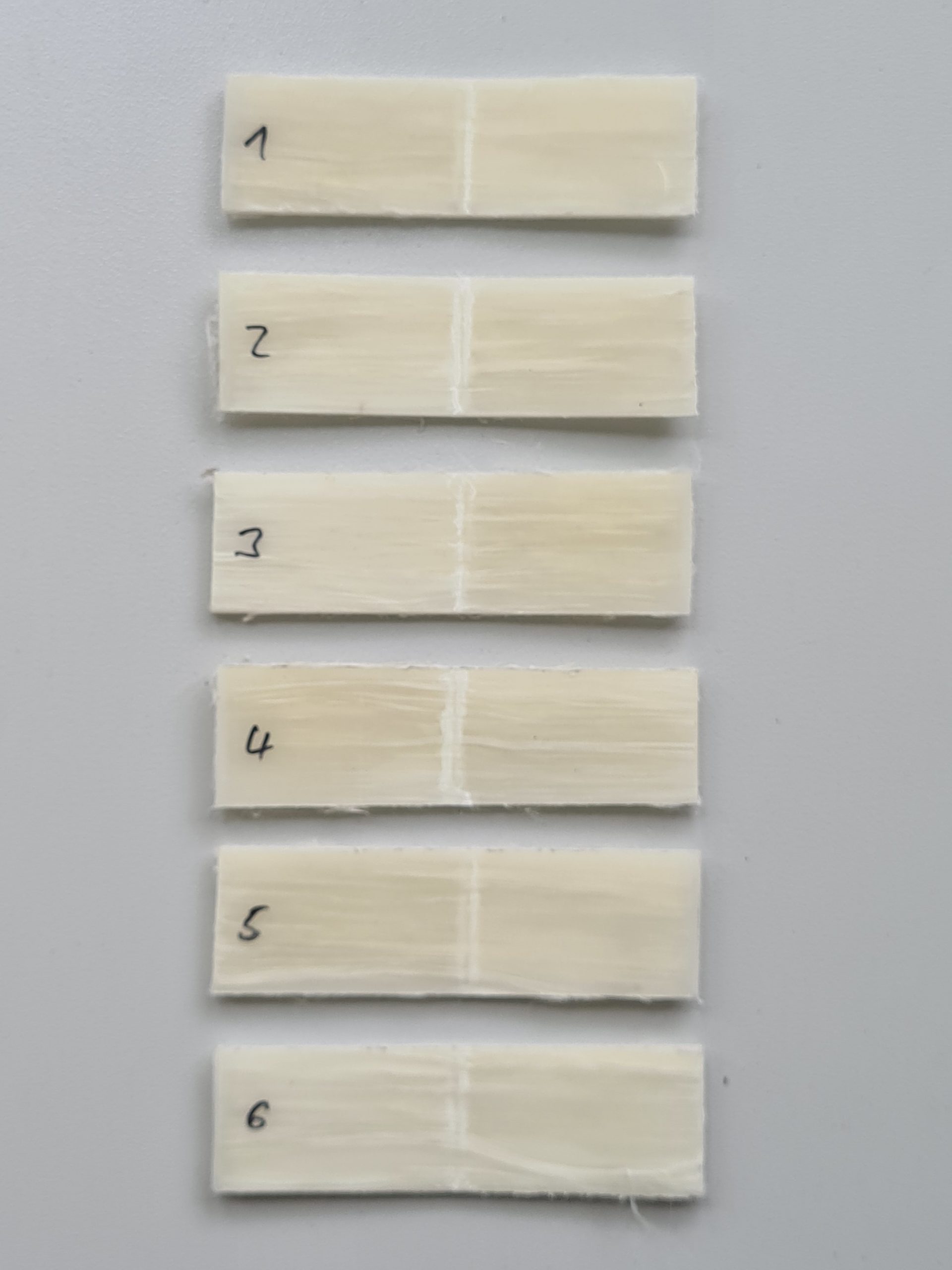

The results are encouraging:

- Mechanical recycling showed that the materials can be processed into granulate and reused in injection moulding. While changes in colour, odour and mechanical strength were observed, the impact resistance of the recycled material even improved compared to reference values.

- Solvent-based recycling effectively removed impurities and additives, significantly improving the material’s quality.

- Potentially hazardous substances such as PCBs were detected only in trace amounts (<1 ppm) – far below legal thresholds.

This proves that even plastics that have been buried in landfills for decades can be recovered and turned into new resources.

Looking Ahead

Together with our partners, we have committed to continuing the project in the long-term. By 2035, we aim to establish a pilot plant directly at the Tännlimoos landfill, initially processing small amounts and later scaling up production. Our ambition is to demonstrate that circular economy principles can also be applied to legacy waste.

For me personally, this project is a milestone: it connects my responsibility for landfill management with the opportunity to return plastics to the value chain – and to contribute to a more sustainable construction and raw materials industry.

by Lydie Krüger, Team leader of Recycling and Disposal, JURA Materials

Sulzer / Mammut – Melt spinning of sustainable fibres for belts and straps in outdoor applications

Time to shine light on a milestone on our road to a more sustainable textile industry is being achieved through the collaboration of Sulzer, Mammut and FHNW. The project’s central focus is the development of more responsible solutions based on bio-based materials, addressing a critical issue – the prevalent use of petroleum-based materials that are neither environmentally friendly nor recyclable.

Sulzer, a provider of thermal separation and polymerization licenced technologies for bio-based polyesters such as polylactic acid (PLA), and Mammut, the Swiss outdoor brand as the end-user, have joined forces with FHNW to create a transformative solution. The project adopts a holistic approach, commencing with design thinking, considering end-user demands for more resourceful one-material solutions and moving backward to the spinning process and advanced polymer formulations.

Mammut’s commitment to the UN Fashion Industry Charter for Climate Action underscores the project’s climate-conscious foundation. They are determined to halve greenhouse gas emissions within the next decade and achieve net-zero emissions by 2050. The project aligns with Mammut’s endeavor to reduce carbon emissions across its value chain, promoting the transition to renewable energy sources.

The novelty of this project lies in its comprehensive approach, covering end-user requirements, processing, polymer formulation, and scaling. Initiated by Sulzer and FHNW, Mammut joined the team, enhancing the project’s strength and potential for success.

The project envisions substituting fossil-based polymers, currently consumed in Switzerland and the European Union, with bio-based materials. While the specific target market remains unspecified, the objective to reduce CO2 emissions and decrease fossil product use is clear.

This initiative brings promising benefits, aiming to reduce CO2 emissions, fossil waste, and the dependence on petroleum-based materials. It offers the potential to replace substantial volumes of petroleum-based textiles with more sustainable bio-based alternatives. The obstacles and risks include cost considerations, market acceptance, quality assurance, scaling production, and securing a reliable supply chain.

While the project’s details are clear, a comprehensive Life Cycle Assessment is needed to evaluate its full environmental impact, including raw material sourcing, production, usage, and waste treatment. The project paves the way for a more sustainable textile industry and aligns with the global shift towards more eco-conscious practices.

Sophie Renot, Mammut

Noriware – Redefining sustainable packaging

Noriware, a Swiss start-up founded in 2022, has emerged as a beacon of hope in the fight against plastic pollution. Equipped with a ground-breaking technology developed in collaboration with ETH Zurich and FHNW, Noriware set out to revolutionise the packaging industry. Their goal? To find a long-term and sustainable solution to the global plastic problem. Their weapon of choice? Algae-based packaging materials that can be 100% composted at home, and in an unprecedented timeframe. Noriware’s journey began with a serendipitous encounter in Mexico, where HSG student Jessica Farda noticed an abundance of algae on the beach. This simple observation gave her an idea. Could algae be the answer to our plastic problem? Jessica returned to her studies and immersed herself in research on the potential of algae as a sustainable resource for bioplastics. In the humble surroundings of her kitchen, she conducted experiments that would lead to a potential breakthrough in the search for environmentally friendly packaging. In September 2021, she joined forces with the Department of Materials Science at ETH Zurich, providing important expertise in materials science. In May 2022, Jessica’s path took a decisive turn when she met her co-founder Stefan Grieder, resulting in a collaboration with the Institute of Plastics Technology and Engineering at the FHNW thanks to the Innovation Booster “Plastics for Zero Emissions” award, adding essential expertise in polymer chemistry and engineering. In September 2022, Noriware AG was officially founded in Aargau and, with the substantial support of the Aargau Research Fund, the cooperation with the University of Applied Sciences continued. In May 2023, the start-up founders succeeded in securing a pre-seed financing round of over 1 million Swiss francs, enabling them to expand their own laboratory infrastructure in Lupfig, Aargau, and launch larger pilot projects with industry partners. With the support of Professor Dr. Markus Grob and Prof. Dr. Christian Brauner, Noriware is well on its way to even greater success. Noriware will continue to expand its product portfolio and contribute to a sustainable future. The company is on its way to redefine the packaging industry and to stimulate a change in corporate thinking for the benefit of the environment, people and the economy.

Ensinger Composites Schweiz GmbH – Self reinforced bio-based polymers

This forward-thinking project embarks on the mission to make composite materials more sustainable through the development of self-reinforced biobased polymers. The approach underpinning this endeavour is the concept of “self-reinforced polymer composites” (SRPCs) or “all-polymer” composites, where a polymer matrix is reinforced by means of fibres of the same polymer. The ingenious aspect of SRPCs is that they offer enhanced fiber-matrix interfacial adhesion and, more crucially, complete recyclability without the need for the arduous separation of fibre and matrix.

The project’s thematic focus revolves around creating biobased SRPCs, introducing a novel dimension to sustainable composite recycling. The capacity to use entirely biodegradable bio-sourced composite materials promises to optimise waste disposal, offering a recycling solution where none existed before. The degree of innovation here is exceptionally high.

The impact of this initiative extends to the heart of the composite industry. As the demand for lightweight design surges, the use of traditional composites like glass and carbon fibers with thermoset matrices presents significant recycling challenges. The project’s approach opens the door to the development of 100% recyclable materials.

Moreover, the secondary objective of developing not just bio-sourced but also bio-degradable materials shifts the need for recycling to composting, particularly vital for components where traditional recycling is impractical or uneconomical.

The funds allocated to this project will facilitate the melt spinning of selected polymers, paving the way for critical spinning trials, fibre processing, characterization, and comparison to the requirements set by Ensinger, the project partner. This collaborative process will enable further refinements in polymer selection and process parameters, ultimately leading to the production of fibres suitable for the composite industry.

The project is structured into work packages that include polymer selection and characterization, melt spinning of fibres, feasibility testing for self-reinforced polymer plates, and the development of process routes for textile production. Completion of WP2 and WP3 is vital in demonstrating the potential of self-reinforced polymers for composite materials.

In sum, this project is a pioneering step towards the future of sustainable, recyclable composite materials, bringing innovative solutions to the core of the composite industry.

Niccolo Pini, Ensinger Composites Schweiz GmbH

![1688970335674[97]](https://plastics4zeroemission.ch/wp-content/uploads/2023/10/168897033567497.jpg)

V Carbon – Recycled carbon fibres for Sports Industry

In the pursuit of innovation, V Carbon GmbH stands as a pioneering force in the realm of recycled carbon fibre (rCF) intermediates. Their latest venture focuses on establishing a market for rCF yarn-based products, known for their cost-effectiveness and remarkable mechanical performance, making them ideal candidates for application in load-bearing structures.

At the heart of this endeavour lies the objective of winding tubular structures with yarn and a thermoset matrix to demonstrate their suitability for load-bearing applications. The technical innovation crucial to this project is the development of a suitable impregnation and winding method for recycled yarn, a task of immense significance in the world of sustainable composites.

The project’s objectives encompass demonstrating the feasibility of rCF yarn winding with thermoset matrix systems. This involves defining optimal processing parameters for winding and yarn impregnation, assessing the mechanical properties of tubular wound structures, and creating a benchmark application.

The benchmark application, a high-performance racing bicycle frame, will serve as a testimonial to the project’s capabilities and achievements. Collaborating with esteemed German companies, SPIN Siebert & Schörner GbR and CG TEC Carbon und Glasfasertechnik GmbH, further underscores the commitment to excellence and practicality by design thinking methods.

V Carbon GmbH’s project not only promises a groundbreaking development in the realm of rCF but also emphasizes the importance of sustainable innovation and its impact on load-bearing structures. This initiative sets the stage for advancements that have the potential to revolutionize the composite industry by paving the way for cost-effective, mechanically robust rCF yarn-based products.

Leo Walker, V Carbon

Sika Technology AG – Carbon Green

In the ever-evolving landscape of sustainable materials, SIKA and the Institutes of Biomass and Polymer Engineering at FHNW have embarked on a groundbreaking collaboration. Their mission: to usher in an innovative solution by replacing carbon black with biochar in various bonding solutions of SIKA.

The project’s foundation lies in a critical evaluation of current sealants formulated with recycled carbon black, which have fallen short of desired standards. Encouragingly, raw biochar grades have emerged as promising alternatives from both pigmentation and reinforcement perspectives.

The innovation at hand is two-fold. Firstly, it involves the introduction of biochar, a negative emission material originating from waste biomass streams. This not only promotes sustainability but also establishes a carbon-creditable business model, aligning with SIKA’s goal of environmental responsibility. Secondly, the collaboration between SIKA and the Institutes of Biomass and Polymer Engineering offers a holistic approach to efficiently address the entire process, from biochar production to the final product, facilitating swift prototyping.

The potential impact of this initiative is immense. By replacing carbon black with biochar, SIKA has the potential to save a remarkable 37.4 million tons of CO2 equivalent emissions over the next years. Such a solution is unprecedented in the market, and its positive ripple effects can extend beyond bonding solutions to other sectors, including automotive and wind turbines.

Methodologically, this collaboration leverages the expertise and equipment of FHNW in biochar production and polymer engineering, offering a unique advantage for SIKA. The project’s structure, from screening different biochar materials to in-house biochar production and evaluation, ensures a comprehensive approach.

Moreover, this project promotes gender and diversity inclusion, further enhancing its value and potential for success. Together, SIKA and the Institutes of Biomass and Polymer Engineering are paving the way for a more sustainable and environmentally responsible future.

The Carbon Green team, Sika Technology AG

Connova – Reversible hybrid metal-composite connections for sustainable assemblies

A groundbreaking project, driven by Connova, OST, and FHNW, is poised to transform the realm of composite materials. Focused on reversible techniques for joining and later recycling thermoset composites, it champions innovation and circularity. This initiative not only aims to cut weight and fuel consumption but, more importantly, to slash CO2 emissions by finding reliable, cost-effective methods for joining fiber-reinforced composites. These techniques facilitate repair, reuse, re-design, and recycling, substantially reducing the CO2 footprint of these energy-intensive components.

The project embarks on a pioneering journey to explore structural joining techniques for thermoset composites, designed for easy detachment at the end of their lifespan. Novel methods include debonding epoxy adhesives with embedded iron particles, a potentially groundbreaking solution, and the innovative use of thermoplastic joining for thermosets.

Collaboration between Connova, OST, and FHNW emerged in response to Connova’s challenge, demonstrating the power of the Innovation Booster platform to bring diverse expertise together. Connova, as an implementation partner, stands to gain invaluable knowledge and tools to offer customers highly efficient, recyclable thermoset composite solutions, creating a competitive edge and opening new avenues for sales.

The project also aligns with Connova’s sustainability goals, promoting the extended lifespan, repair, and reuse of components, as well as efficient recycling, ultimately reducing the demand for petrochemical resources and lowering CO2 emissions.

With FHNW and OST contributing their expertise and laboratory facilities, the project ensures a robust methodological approach to address the industry’s needs.

The project’s scope includes evaluating various joining technologies for reversible composite-composite or composite-metal connections, with work packages structured to achieve these goals. Successful completion of WP1 and WP2 is pivotal in demonstrating the potential of the proposed joining and disassembly concepts.

The project signifies a remarkable stride towards achieving sustainability and circularity in the composite materials domain, bringing innovative, environmentally conscious solutions to the forefront.

Sebastian Preiss, Connova